Smile, new robotics technology is on its way! ©2024 Takeuchi et al. CC-BY-ND –

Smile, new robotics technology is on its way! ©2024 Takeuchi et al. CC-BY-ND –

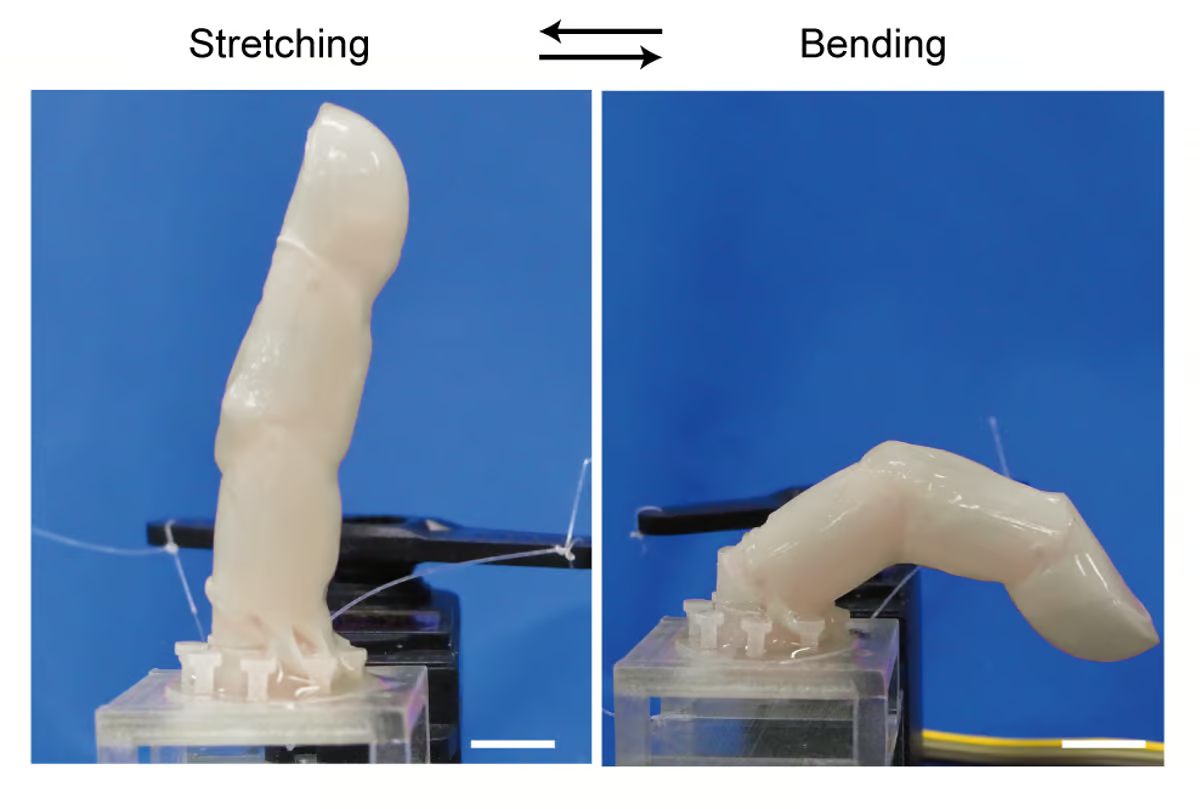

Two years ago, Prof. Shoji Takeuchi and colleagues at the University of Tokyo successfully covered a motorized robotic finger with a bioengineered skin made from live human cells.

It was hoped that this proof-of-concept exercise might pave the way not only for more lifelike android-type robots, but also for bots with self-healing, touch-sensitive coverings. The technology could additionally be used in the testing of cosmetics, and the training of plastic surgeons.

While the skin-covered finger was certainly an impressive achievement, the skin wasn’t connected to the underlying digit in any way – it was basically a shrink-to-fit sheath that enveloped the finger. By contrast, natural human skin is connected to the underlying muscle tissue by ligaments.

Among other things, this arrangement allows us to exhibit our various facial expressions. Additionally, by moving along with the underlying tissue, our skin doesn’t impede movement by bunching up. For this same reason, it’s also less likely to be damaged by getting snagged on external objects.

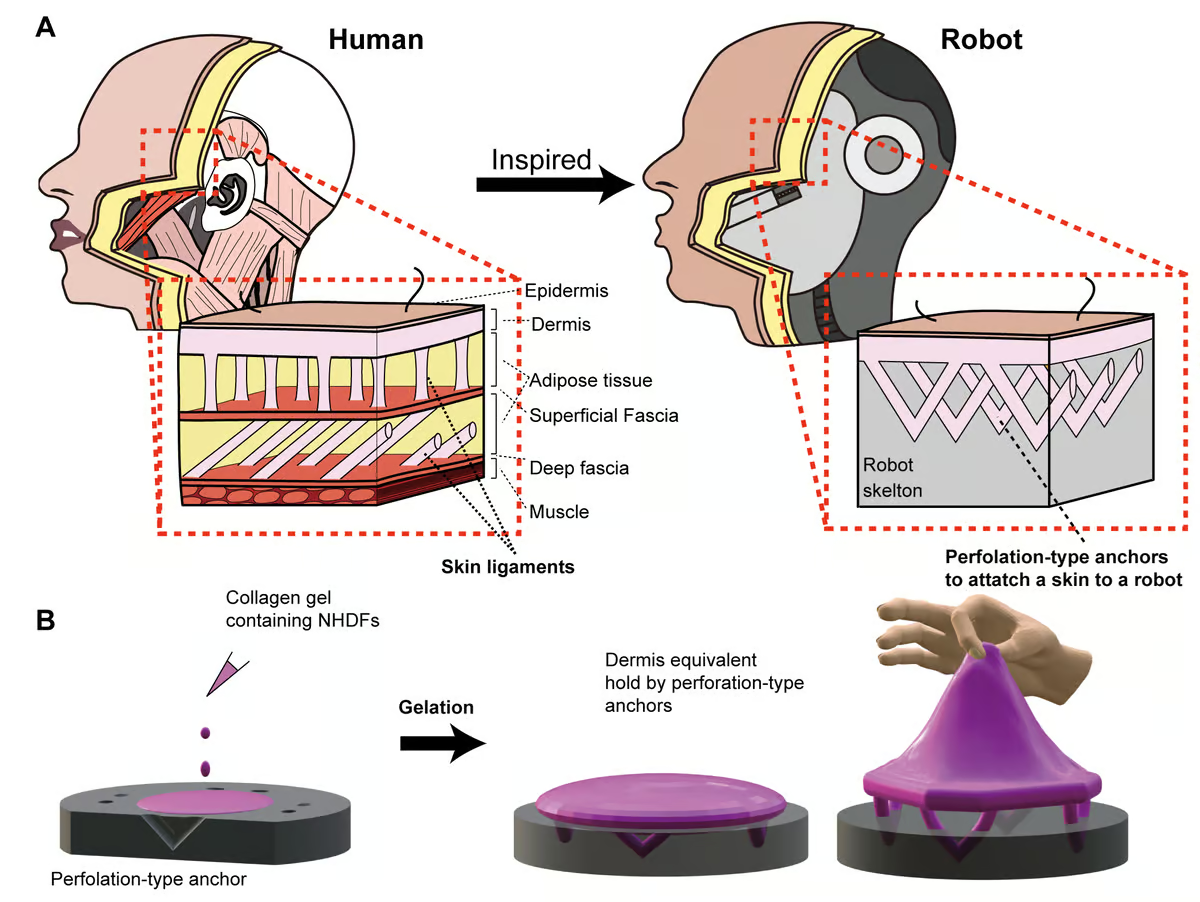

Scientists have previously attempted to connect bioengineered skin to synthetic surfaces, typically via tiny anchors that protrude up from those surfaces. These pokey anchors detract from the skin’s appearance, however, keeping it from looking smooth. They also don’t work well on concave surfaces, where they all point in towards the middle.

With such limitations in mind, Takeuchi and his team recently developed a new skin-anchoring system based on tiny V-shaped perforations made in the synthetic surface.

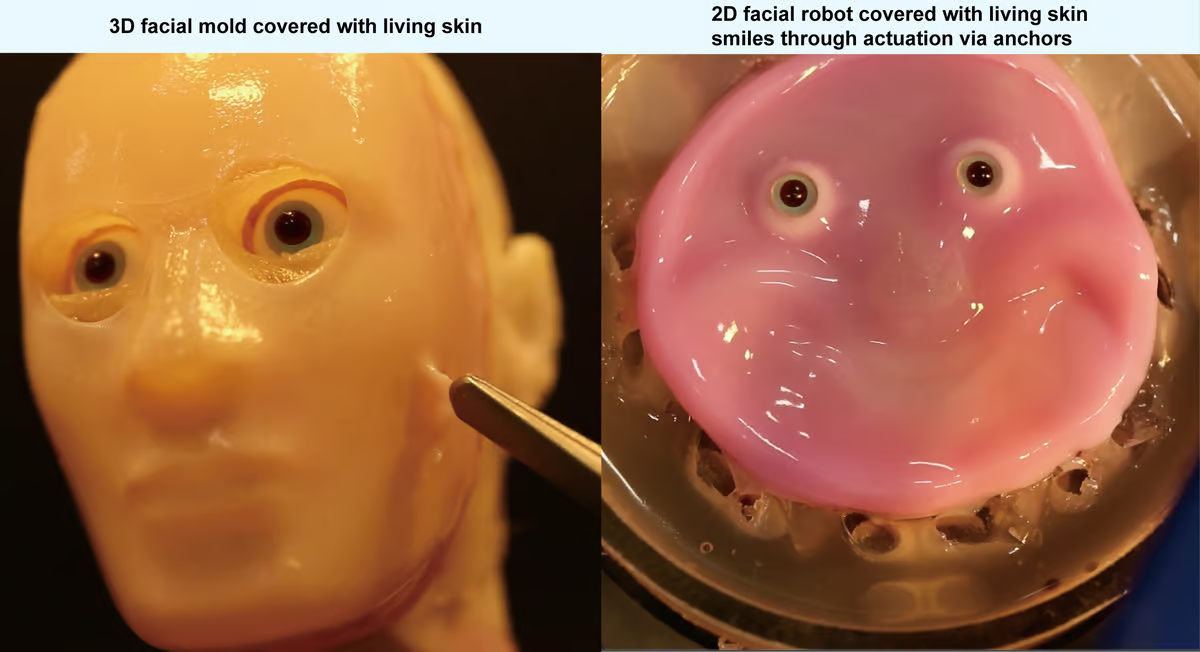

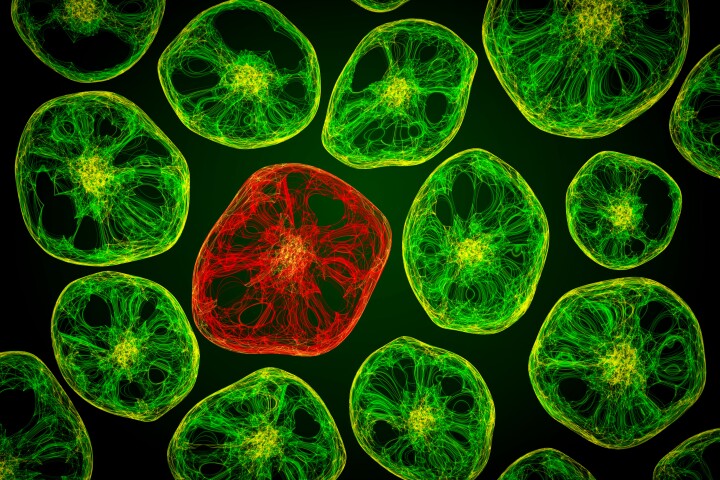

The scientists created a human facial mold that incorporated an array of these perforations, then coated that mold with a gel consisting of collagen and human dermal fibroblasts. The latter are cells which are responsible for producing connective tissue in the skin.

Some of the gel flowed down into the perforations, while the rest stayed on the surface of the mold. After being left to culture for seven days, the gel formed into a covering of human skin that was securely anchored to the mold via the tissue within the perforations.

In a second experiment, perforations were made in a silicone rubber substrate, to which the gel was subsequently applied and then allowed to culture. The end result was a simplified human-skin face that could be made to smile by moving two rods connected to the substrate.

Needless to say, some work still needs to be done before the technology can be utilized in truly lifelike robots.

“We believe that creating a thicker and more realistic skin can be achieved by incorporating sweat glands, sebaceous glands, pores, blood vessels, fat and nerves,” says Takeuchi. “Of course, movement is also a crucial factor, not just the material, so another important challenge is creating humanlike expressions by integrating sophisticated actuators, or muscles, inside the robot.”

A paper on the research was recently published in the journal Cell Reports Physical Science.

Source: University of Tokyo View gallery – 5 images

–

Please keep comments to less than 150 words. No abusive material or spam will be published.