Materials Nexus and the University of Sheffield team to create the AI-identified MagNex material. Materials Nexus –

Materials Nexus and the University of Sheffield team to create the AI-identified MagNex material. Materials Nexus –

With the world moving away from internal combustion engines and gradually embracing electric mobility, the demand for compact, high-power motors is rapidly rising. By far the most popular option in the automotive industry right now is the permanent magnet motor, which powers upward of 80% of modern electric vehicles.

Materials Nexus estimates that demand for permanent magnets will grow tenfold by 2030, in the EV industry alone. And it’s not just electric cars and trucks, either. Permanent magnet motors are in demand for many applications, including robotics, drones, wind turbines and HVAC equipment.

The problem is, the rare earth materials used to create the most powerful magnets and most efficient, power-dense motors – materials like neodymium and dysprosium – require damaging mining and expensive, energy-intensive processing. With its world-largest EV market, China has emerged as a leader in both mining and processing of rare earths, pulling as much as 70% of the world’s rare earths out of the ground while processing closer to 90%. That gives the country monopoly-like control over the essential materials, leaving other markets exposed to supply disruptions and pricing fluctuations.

The search for alternatives is on, and some automakers and suppliers are starting to develop and incorporate magnet-free motors. Others, including Tesla, are pursuing permanent magnet designs free from rare-earth materials.

Rare-earth-free magnets certainly sound like an intriguing solution, but they can be difficult to formulate and less powerful than traditional rare-earth magnets. Niron Magnetics has developed what it calls the world’s first high-performance rare-earth-free magnets, using a mix of abundantly available iron and nitrogen, but it’s been researching and developing it for over a decade and still isn’t quite ready for mass production.

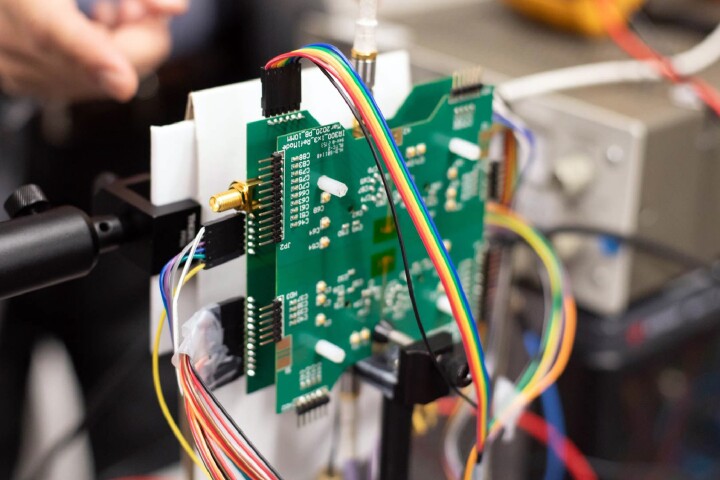

Materials Nexus is letting the world know it’s here to help. It believes it has just what contemporary and future magnet startups need to identify and develop rare-earth-free magnetic materials, and by substituting AI for old-fashioned trial-and-error, it believes they can do so at a pace hundreds of times faster than has been traditionally possible. It says its AI platform can identify rare-earth-free magnetic materials in a matter of days or weeks, in contrast to the years and decades it’s taken in the past.

Rather than simply spout impressive numbers, Materials Nexus has already used its AI platform to identify a rare-earth-free permanent magnet it’s named MagNex. The AI analyzed more than 100 million rare-earth-free material compositions before it landed on MagNex, factoring in variables such as cost, supply chain security, performance and environmental impact.

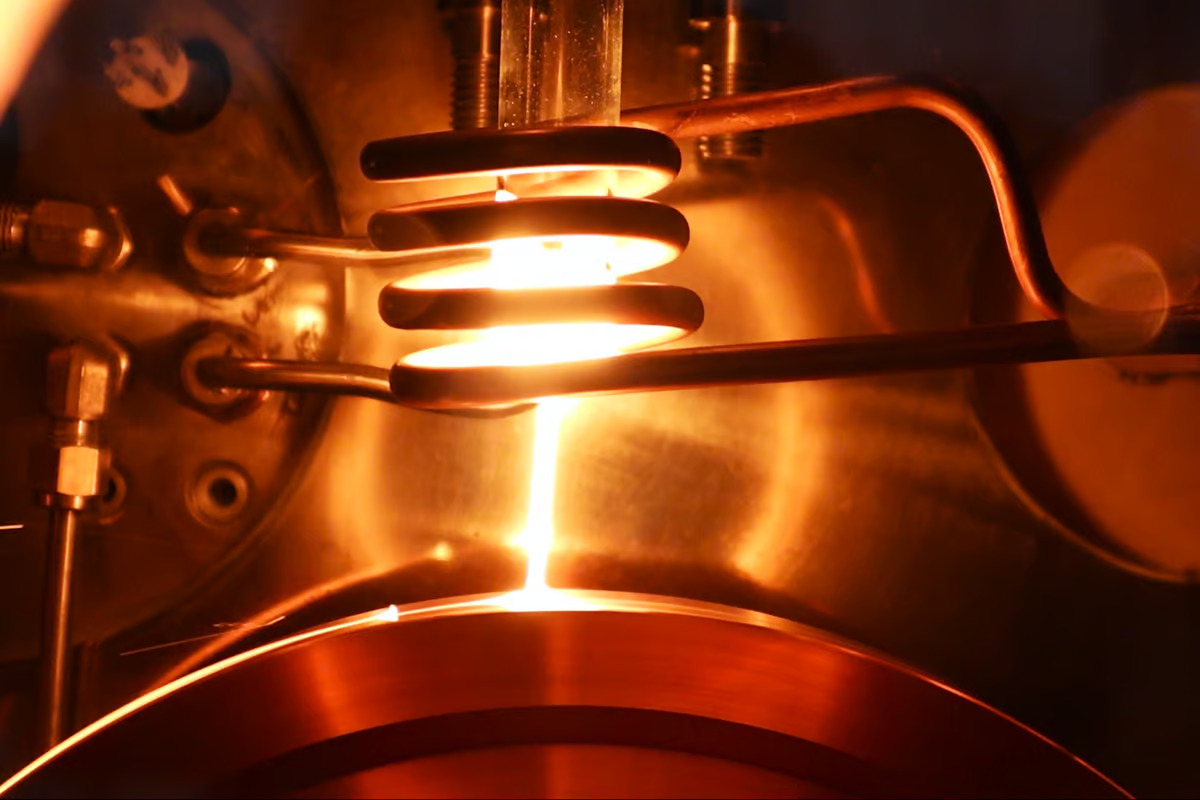

After the AI did the heavy lifting, Materials Nexus synthesized and tested MagNex with help from the Henry Royce Institute at the University of Sheffield. In three months, the company had done work that would have taken years prior to its AI system.

Furthermore, Materials Nexus says MagNex can be produced at 20% the material cost of currently available rare earth magnets, with a 70% reduction in material carbon emissions.

“We’re really excited that our first interaction with Materials Nexus has yielded such a hugely positive outcome,” said professor Iain Todd, metallurgy and materials processing, University of Sheffield. “The combination of Materials Nexus’ approach of using AI for materials discovery and the world-class facilities we have for manufacture of advanced alloys in the Henry Royce Institute here at Sheffield has allowed a novel magnetic material to be developed with breathtaking speed.”

While a brand-new rare-earth-free magnet added some serious juice to this week’s announcement, it’s far from the only possible use case for Material Nexus’ AI. The company says the AI will be useful for all kinds of industries, helping to identify and create the next generation of cutting-edge materials driving new technologies and CO2e emissions reductions. It plans to work with industrial partners toward accelerating the discovery of viable, cost-effective and sustainable next-gen materials.

“Our platform has already attracted widespread interest for various products with applications that include semiconductors, catalysts and coatings,” said Materials Nexus CEO Dr. Jonathan Bean. “I look forward to seeing the role it will play in supporting market demand for the creation of novel materials to help address increasingly pressing supply chain and environmental issues.”

As do we. We also look forward to seeing if MagNex becomes a viable magnet alternative for permanent magnet motors, whether aimed at electric mobility or one of the other applications for which such motors will remain in high demand.

Source: Materials Nexus

–

Tags

What will happen to the children who are employed in the mining of rare earths? Will they be retrained to labor elsewhere, like gold mines?

The Chinese sure know how to Capitalize important industries. Super Capitalists! This technology gives hope that we will be able to compete, and/or maintain parity.

So why aren’t they going into production?

This appears to be great news – Non-Rare-Earth or NRE magnet synthesis with 70% less environmental impact in production! Any mass to strength comparisons to current RE magnets? Are they similar in brittleness, in longevity, and in effective operating temperatures? Materials Nexus gave no real specifications, just “high-performance permanent magnets” press release. Why is this a regurgitation of Corporate Hype? Wonderful concept, good use of AI, but is this equal or better than RE magnets?

No mention in the article if this is actually going into production. It all sounds good, but we’ve been hearing wonderful stuff about battery tech and fusion tech for decades, and we’re still waiting.

Did AI generate the title of this article as well!?…. Because it makes zero sense.