Crushing cedar chips created a less efficient biofuel than crushing planks, due to the internal structures of the materials. Depositphotos

Crushing cedar chips created a less efficient biofuel than crushing planks, due to the internal structures of the materials. Depositphotos

–

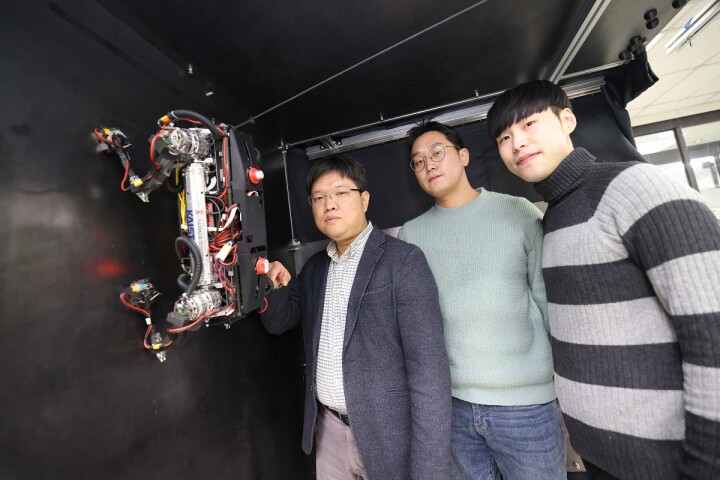

To create a process that would extract moisture from plant matter to such a degree that heat drying is unnecessary, researchers at Okayama University in Japan created a rolling compressor. They then fed cedar wood board, cedar chips, and a species of ginger known as Alpinia zerumbet through the press. All three dehydrated materials were then turned into pellets and burned to evaluate how effectively they functioned as a fuel.

The scientists found that the cedar wood boards and the ginger plants compressed better than the wood chips, something they chalk up to having the internal structures of plant materials laid out in a structured way rather than in the more chaotic way found in wood chips. Think of rolling a tube of toothpaste up from the bottom. You’d be able to extract more from a tube that is straight and hollow than one that is criss-crossed with different channels.

They also discovered that the pellets made from the cedar wood boards yielded a higher heat value than the ginger plants when burned. The cedar pellets burned at a level matching standards set by the Switzerland-based International Organization for Standardization (ISO), while the ginger burned at about 95% of the standard. (The ISO is an international group that sets standards across a wide range of industries.)

“Our method does not require time, a stockyard, or additional thermal drying, allowing for on-site operation,” said study co-author Toshiaki Ohara, Asst. Prof. in the Department of Pathology and Experimental Medicine at Okayama University. “This compressor can squeeze both wood and herbs allowing us to promote biomass electric power generation using locally grown plants. These characteristics are beneficial for advancing local sustainability.”

Furthermore, even though the ginger plants burned less efficiently than optimal, they did yield the most water-soluble lignin, a compound that has long been an offshoot of the wood pulp and paper industry and is getting more and more attention for its potential uses, including its application as an antiviral.

A 2021 study showed that heat-drying of plant material can negatively affect the water solubility of lignin. This is one of the reasons why the new heat-free method of drying the plants holds promise, as water solubility can expand a substance’s applications. In the Japanese research, the lignins extracted from both the ginger plants and, to a lesser extent, the cedar chips, effectively inhibited the activity of the viruses responsible for influenza and porcine epidemic diarrhea. Previous studies have shown that lignin-based coatings were effective in defeating herpes simplex virus type 2 and HIV.

“The non-chemically extracted water soluble lignin obtained by this method can find applications in the fields of medicine, cosmetics, and livestock husbandry,” said study co-author Dr. Yuta Nishina from the Research Core for Interdisciplinary Sciences at Okayama University.

The research has been published in the Journal of Material Cycles and Waste Management.

Source: Okayama University via EurekAlert

–