Researchers have developed a novel method for storing and handling valuable biological materials. Depositphotos

Researchers have developed a novel method for storing and handling valuable biological materials. Depositphotos

Biological materials that come from human cells, like enzymes, mRNA, proteins, and antibodies, are crucial to developing new medicines and diagnostic tests. And they’re fragile. Extremely temperature-sensitive, they require a constant ambient temperature during storage, handling, and transportation. If not stored or handled correctly, these materials can degrade and become inactive, which can be costly.

Most biological materials are stored as liquids or freeze-dried powders and kept at low temperatures for the duration of their shelf life. This is achieved through a complex, integrated system of refrigerators and freezers known as the cold chain. This requires a significant investment in equipment and infrastructure, making it expensive to maintain, and makes the cold chain prone to shipping delays, power outages, equipment failure and human error.

To address the issues associated with the cold chain, researchers at California Polytechnic State University (Cal Poly) have developed a groundbreaking platform for storing and transporting biological materials that they say has great potential for use by medical and scientific communities.

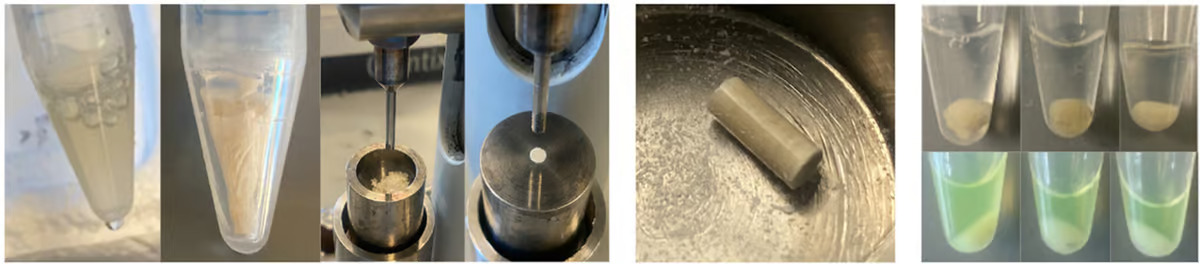

To develop their new storage platform, the researchers took inspiration from the home medicine cabinet, where medications are stored in the form of liquids, powder-filled capsules, and tablets. So they set about developing a platform based on the humble tablet that would enable biological materials to be compressed into a solid state.

“Just as tablets have changed the way we take medications, the solid-state storage platform opens new possibilities for how we handle and use biological materials, unlocking the potential for existing therapies and emerging biotechnologies,” said Javin Oza, corresponding author of the study.

Tablets provide advantages to the storage and handling of biomaterials, or biologics, that the cold chain doesn’t. For one thing, they can be stored at room temperature. And, when they’re required, the tablet can be dissolved in water.

“Our innovation makes storing and using biologics as easy as an Alka-Seltzer tablet, just drop it into water, mix, and it’s ready to go,” said Oza.

The researchers relied on a cell-free protein synthesis (CFPS) system integrated into their solid-state tablet platform. CFPS rapidly produces proteins using a solution containing biological machinery components such as ribosomes, enzymes, DNA, and amino acids but without using living cells. CFPS has been used in pharmaceutical discovery and production, the creation of on-demand vaccines and biosensors that detect pathogens.

Here, the components of the CFPS reaction were mixed, and a stable preparation was created by freezing and dehydrating the frozen product under a high vacuum in a process called lyophilization. It was then pressed into a solid-state pellet.

The researchers were able to demonstrate that the solid-state system was able to support a complex biochemical mixture. When a pellet containing cell machinery capable of decoding genetic information into making RNA and proteins was added to water, it reactivated and decoded information as if it were still within the cell. They then integrated the CRISPR-Cas9 gene editing system into a pellet and found it was similarly activated after being stored in a solid state.

The researchers say their novel tablet-based storage and handling method is simple to use and doesn’t require specialty training, making it appropriate for broad applications. For example, the room-temperature storage of therapeutics at remote locations where the cold chain is unavailable, ready for on-demand activation.

But they see applications beyond improvements to the storage and handling of biological materials. Making modifications to tablet coatings could help the solid-state storage platform withstand environmental extremes like heat, humidity and chemicals. These sorts of changes may eventually enable injectable medications such as insulin to be taken in oral form.

The study was published in the journal ACS Synthetic Biology.

Source: California Polytechnic State University via EurekAlert!

–